Quote:

Originally Posted by EastPete

Interesting theory, which seems to make sense to me. I am thinking of changing the hydramount on my CDTi (I have already changed the lower engine and gearbox mounts) to remove some residual vibrations at certain engine speeds that result in a dashboard vibration and an irritating buzz from the door locking button on the drivers door (right next to my lughole !). I am also suspicious of the poorer refinement on my present car from it running on lower profile tyres on alloys, compared to 15 inch steel wheels with higher profile rubber on my earlier 75, which was much more refined. In fact, yesterday, I ordered a set of 15 inch steel rims from a scrapyard that are breaking a basic spec 75 classic - 4 rims for 60 quid - I plan to put Goodyear Vector 4 seasons tyres on them (60 pound each for the 195/65 R15s from mytyres) - I expect a quieter, smoother ride on these, but I'll keep folks on here updated.

BTW - is the hydramount change difficult ? - a basic 'how to' post would be helpful, although I can probably work it out for myself once I get the spanners out !

Thanks

Pete

|

The 15" wheels, steel or alloy, will obviously give a softer, quieter ride with a decrease in cornering ability.

The Hydramount is easy to change unless the mount itself proves difficult to unscrew from its mounting. It has a metal band around it with cutouts in

it which a special tool fits to unscrew it. You can use a drift on these flats. If it proves difficult then, on the diesels, it is easy to pour some releasing fluid into the bottom cup in which the Hydramount sits and leave to soak in. Mine released after five minutes. The petrol models do not have the bottom cup fitted. You must drop the engine undertray, remove one of the 15mm bolts from the lower engine mount and loosen the other one so that the lower mount can hang free and not cause the engine to be

prevented from being swung, at the top, into the correct position to undo the rather large casting which sits on top of the Hydramount. To remove this casting you need to jack up the engine slightly,remove the engine cover, the power steering reservoir bracket (easy), the nut on top of the Hydramount, and four long 15mm bolts holding the casting to the engine.

Then, with the two 15mm bolts connecting the top link to the secondary engine mount (bolted to the O/S inner wing by three 15mm bolts) removed the whole casting complete with the linkage will lift off.

I will try to add some pics next.

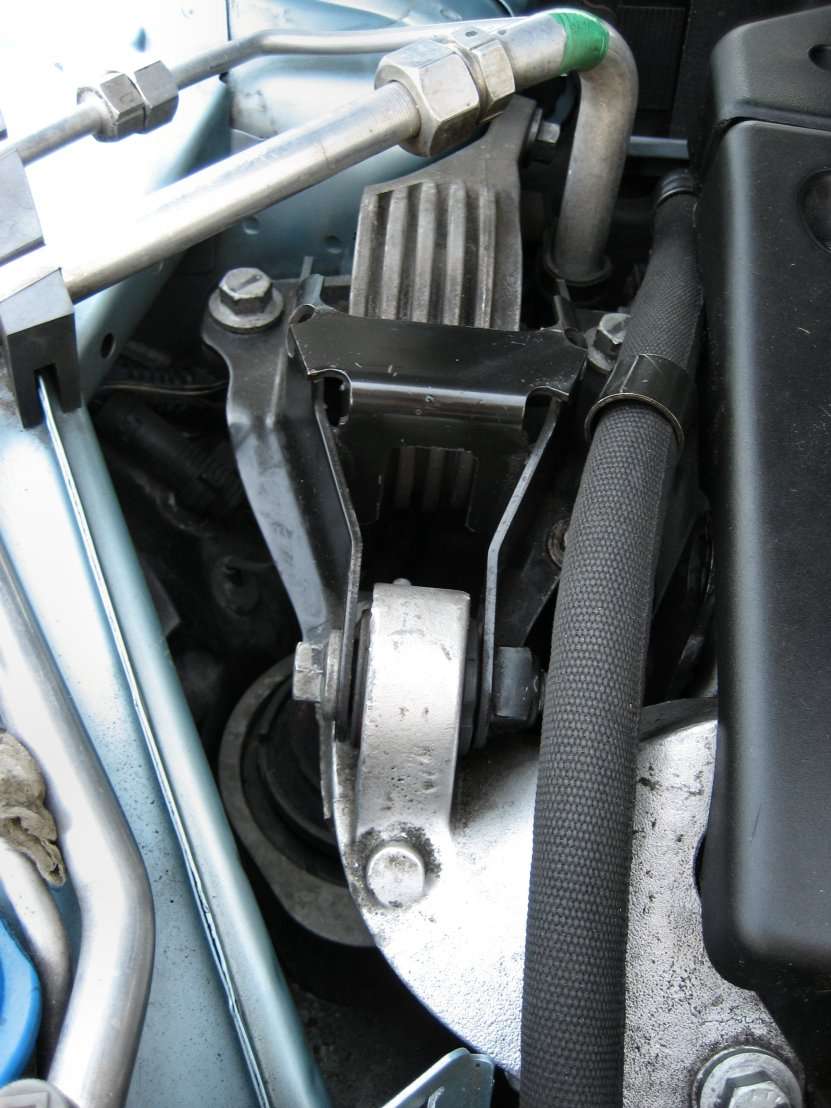

This pic shows the two 15mm bolts which need to be removed on the link (the two with a black line across them). Apart from removing the top nut from the Hydramount, and the upright bracket holding the power steering pipe that is all in this area. In the bottom R/H corner of the pic you can see one of the long 15mm bolts holding the top casting to the engine. More pics to follow.