|

||

|

|

||

|

|

||

|

|

#1 |

|

Posted a thing or two

Rover 75 2.0 V6 Auto Join Date: May 2011

Location: Sandnes - Norway

Posts: 1,560

Thanks: 64

Thanked 283 Times in 174 Posts

|

Hi All,

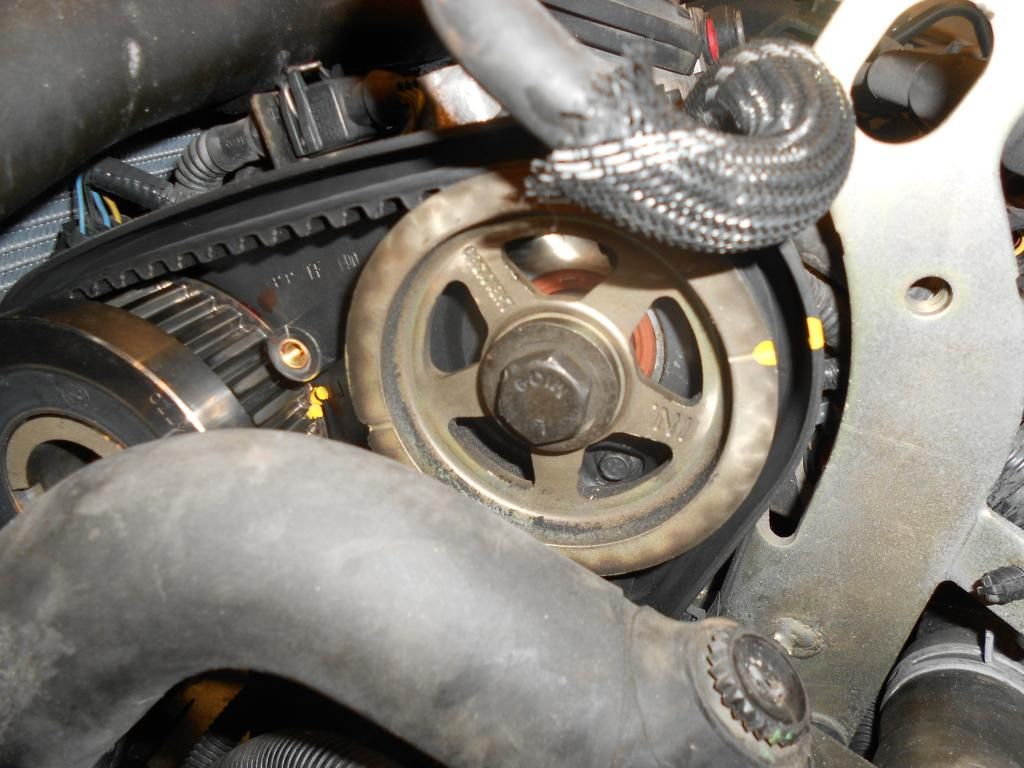

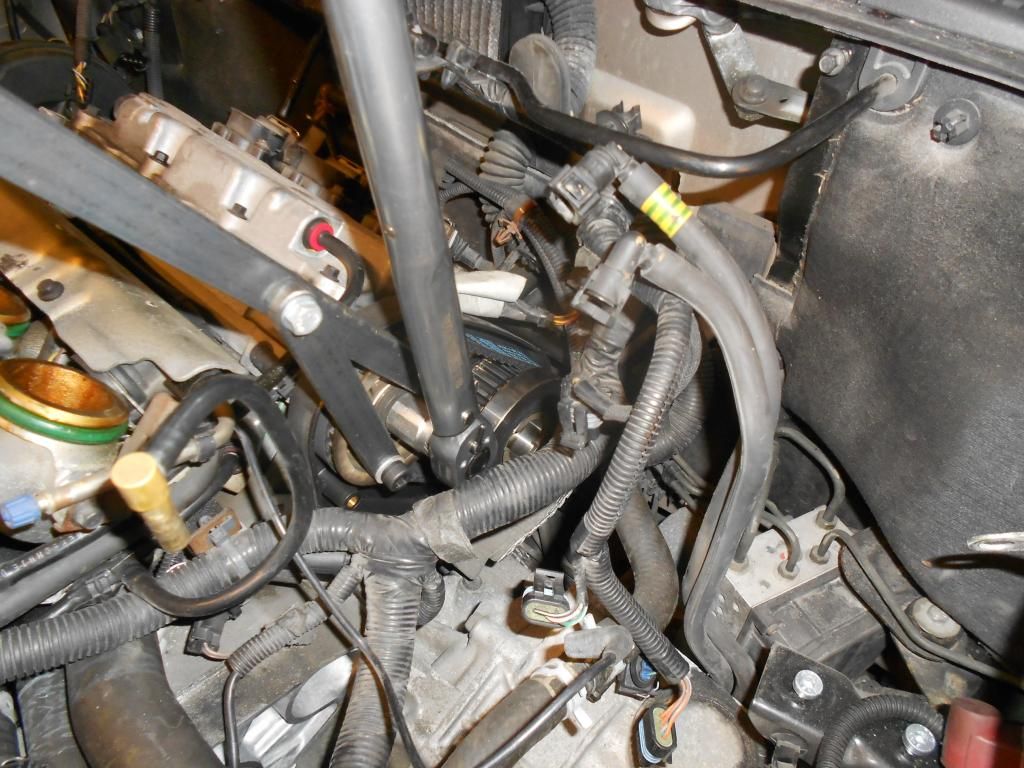

I have for a long time planned to do a cambelt change on my KV6 as they have "expired" by date 2 years ago, but has a low mileage. I have slept well at night, but decided to have this done for the piece of mind. DMGRS supplied me with a KV6 TB kit with WP for a nice price and necessary inlet manifold gaskets and sprocket bolts was purchased. I had no special tools available, so I decided to go for the "haynes way" without the special tools. I decided to park up the car in the garage for this job and use the time needed to do the job throughly without rushing anything. I also did some research up front on this forum and found a lot of useful tips before starting. So basically, this is what I have done so far: 1. Parking the car up in my garage, put on jackstands, wheels and inner wheel arches removed. Oil and coolant drained from the engine:  2. Battery + box, air filter box and upper inlet manifold removed.  I found it hard to remove the 2 screws securing the rear of the inlet maniflod to the rear bank. I removed the bulkhead plate to gain better access. The "sad thing" is that this car has been through a cambelt earlier in its life and there is several minor issues left with that job. One of the rear bolt fixings in the upper inlet manifold was broken of and a bolt was missing in the other end. They have also managed to use tooling to remove the upper inlet manifold and make indents in the inlet manifold flange seal surface.   3. I decided to do the rear belts first before removing the RH engine mount, based on some advice found in an earlier thread. The covers was removed, finding another issue where one of the bolts where over-tightened and making a thread insert int the inner cambelt cover to came loose. The engine was turned to the "safe position" as described in the haynes manual and the position of the rear sprockets was marked up for re-alignment later on.  A simple sprocket holding tool was fabricated from some steel bars, making me able to hold the sprockets stationary while loosen and tighten the sprocket bolts without placing any strain on the cambelts and camshafts.  The rear sprocket bolt in the inlet camshaft was loosened and the sprocket was gently removed from the camshaft. The exhaust sprocket moved sligthly when this was done. A new cambelt was put in place and the inlet camshaft sprocket was put back on with a new sprocket bolt. I turned the exhaust camshaft back in the correct position according to my marks with a socket tool on its sprocket bolt while putting the inlet camshaft sprocket back on with its new bolt, tightened with my fingers only. Checking that the alignment was 100%, then torqued and angle tightened (27Nm+90deg) the sprocket bolt using the sprocket holding tool:  Then I did the same procedure for the other rear cambelt and ended up having two freshly installed rear cambelts:  I turned the engine two full revolutions and parked it up in the safe position, tripple checking the alignements to make sure everything was perfect. So far, so good. 4 hours used. I will now proceed with the front end in the next days. The old belts looked to be in a fantastic condition (!). Seems like they lasts a lot longer than their "due date"  Last edited by beinet1; 16th January 2018 at 18:47.. |

|

|

|

|

|

#2 |

|

This is my second home

2007 57 GOLF GTi EDITION 30 DSG Join Date: Nov 2011

Location: Newport Shropshire and Coventry.

Posts: 5,137

Thanks: 2,424

Thanked 1,452 Times in 852 Posts

|

Glad you are brave enough to do it! Ive found that the rear belts always look like new and the main one is the one that gets the strain.

You seem to have it within your skills. You seem to have it within your skills. |

|

|

|

|

|

#3 |

|

Loves to post

MG ZT-T 190 Join Date: Jul 2014

Location: Penrith

Posts: 441

Thanks: 89

Thanked 69 Times in 56 Posts

|

Very pleased you're giving great pictures. Will be tackling mine in the future and it is confidence inspiring.

Great job!

__________________

ZT-T 190 |

|

|

|

|

|

#4 |

|

Gets stuck in

Rover 75 Classic SE 2.0V6 Auto Moonstone Green Join Date: Sep 2008

Location: Roscommon

Posts: 839

Thanks: 315

Thanked 46 Times in 34 Posts

|

The Haynes Manual says to remove the AC Compressor. DON'T cos it's a nightmare to get back on. Remove the 2 bolts on the front and just slacken the 3rd bolt. You'll see what I mean when you get that far. I removed the 3 bolts and it took me ages to get the Compressor lined up.

__________________

[SIGPIC][/SIGPIC] |

|

|

|

|

|

#5 | |

|

Posted a thing or two

Rover 75 2.0 V6 Auto Join Date: May 2011

Location: Sandnes - Norway

Posts: 1,560

Thanks: 64

Thanked 283 Times in 174 Posts

|

Quote:

Thanks anyway  |

|

|

|

|

|

|

#6 | ||

|

Doesn't do things by halves

Rover 75 2.5 Connoisseur Auto (1999) Dealer launch model. Join Date: Mar 2007

Location: Former Middlesex

Posts: 20,338

Thanks: 1,587

Thanked 3,749 Times in 3,181 Posts

|

Thanks for your excellent pictorial account Einar. I'm looking forward to the next instalment. An observation on your experiences so far though:

Quote:

Quote:

Simon

__________________

"Whatever is rightly done, however humble, is noble." Sir Henry Royce. |

||

|

|

|

|

|

#7 | |

|

Posted a thing or two

Rover 75 2.0 V6 Auto Join Date: May 2011

Location: Sandnes - Norway

Posts: 1,560

Thanks: 64

Thanked 283 Times in 174 Posts

|

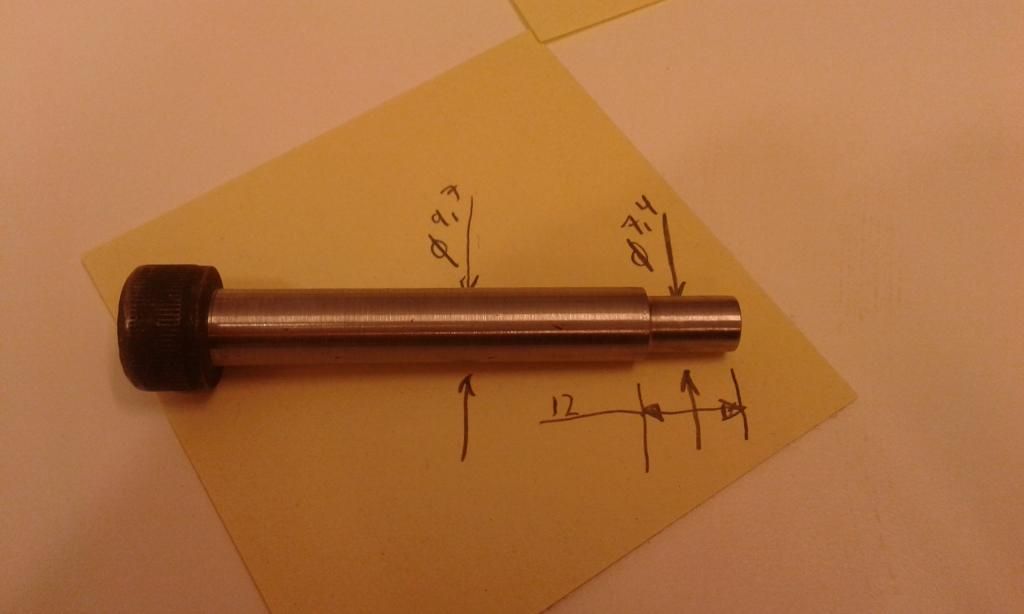

Quote:

You are correct about that  Compared to the MGR special tools, this one is easily made for the home mechanics and also avialable for a resonable prices around: http://www.ebay.co.uk/itm/Laser-2869...item486d96fa4a A flywheel locking pin is also needed. Luckily I have access to a lathe and its quite simple to make this one out of the shank from a M10 12.9 socket head bolt:  Last edited by beinet1; 16th January 2018 at 18:47.. |

|

|

|

|

|

|

#8 |

|

Senior Citizen

Rover 75 2.5 Connoisseur SE,Chrysler 300C,124 Spider, Daytona 955i,Honda XL250 & Royal Enfield 650GT Join Date: Feb 2008

Location: The Kingdom of Wessex

Posts: 6,976

Thanks: 2,391

Thanked 2,685 Times in 1,686 Posts

|

A great thread Einar!

__________________

Let the good times roll............ |

|

|

|

|

|

#9 |

|

Loves to post

MG ZT190+ No.5863 Join Date: Dec 2013

Location: Swindon

Posts: 321

Thanks: 52

Thanked 36 Times in 31 Posts

|

Will be very interested in the rest of this.. great work!

|

|

|

|

|

|

#10 |

|

Posted a thing or two

Rover 75 2.0 V6 Auto Join Date: May 2011

Location: Sandnes - Norway

Posts: 1,560

Thanks: 64

Thanked 283 Times in 174 Posts

|

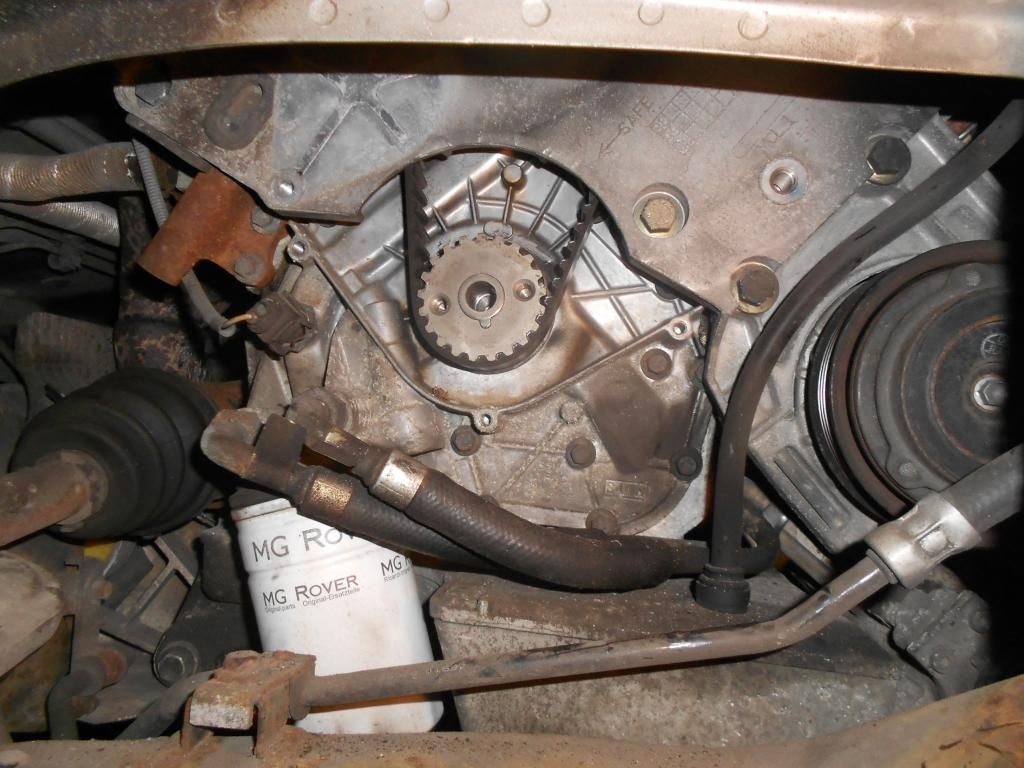

Hi all,

Thanks for the great response  I have some more work done the last evening. I decided to loose the crankshaft pulley bolt as the next step as I have experienced in general that this one is hard to remove. Locking the flywheel properly is often the hard part. There was no clear and good way explained in the Haynes manual to do this. Using the flywheel lock pin was not an alternative as my gut feeling told me that there might be a risk shearing this tiny bolt of if excessive force was needed to remove the bolt. I removed the starter to see if I was able to lock the flywheel in any way through that opening, but that seemed to be pretty impossible. The inside of the crankshaft pulley has a large internal hexagon which may be used with some kind of tooling for locking.  I made a simple flange tool to be used togehter with my sprocket holding tool which fitted inside the crankshaft pulley. It had 3 M10 socket head screws that fitted nicely inside the hexagon. A lot of magic can be done if you have access to a lathe and a proper drilling machine....    The tool was put into place and the arm of the sprocket holding tool resting at the subframe. The flange had a center hole so I could access the pulley bolt with a socket tool:  The pulley bolt was loosened. I was surprised on how much brute "manpower" that was needed to undo that bolt, even with a long armed tool!! Glad I did it this way as the flywheel locking pin would probably be sheared of by this   Maybe this kind of tooling is a bit overkill but it definitely did its job  I guess it could be made a bit simpler. I guess it could be made a bit simpler.Then the tool was removed and crankshaft locked in safe position using the crankshaft locking pin made earlier:  Then it was just proceeding with removing the RH engine mount, AUX belt + pulley and tensioner, PAS pulley and the plastic covers over the timing belt. That was all I had time to that evening. I guess I will have to use my time on the family this weekend, but plan to do the timing belt swap early next week. So far, pretty happy with all of the work done    Last edited by beinet1; 16th January 2018 at 18:48.. |

|

|

|

|

| Thread Tools | |

| Display Modes | |

|

|