|

||

|

|

||

|

|

||

|

|

#11 |

|

Regular poster

MG ZT 1.8T & Lotus Elise S2 (K Series) Join Date: Aug 2012

Location: Leeds

Posts: 67

Thanks: 2

Thanked 4 Times in 3 Posts

|

Hi All,

So the cause of the leak was HGF at the alternator side, glad I caught it before the engine over heated!! Apparently it was impossible to spot without removing the manifold... Quoted £700-800 for Head skim/pressure test, gasket replacement along with new belts, water pump and everything else that comes with it. Should be ready for the road again in a few days time  Chris |

|

|

|

|

|

#12 |

|

Doesn't do things by halves

Rover 75 2.5 Connoisseur Auto (1999) Dealer launch model. Join Date: Mar 2007

Location: Former Middlesex

Posts: 20,344

Thanks: 1,587

Thanked 3,749 Times in 3,181 Posts

|

Hi Chris,

If there's been no overheating then skimming the head is unnecessary. It's best to keep the factory finish. It's been known for some garages to put K-Seal  into the coolant. Make sure yours doesn't do this. into the coolant. Make sure yours doesn't do this.Simon

__________________

"Whatever is rightly done, however humble, is noble." Sir Henry Royce. |

|

|

|

|

|

#13 |

|

This is my second home

Rover75 and Mreg Corsa. Join Date: Nov 2006

Location: Sumweer onat mote o'dust (Sagin)

Posts: 21,752

Thanks: 341

Thanked 3,660 Times in 2,924 Posts

|

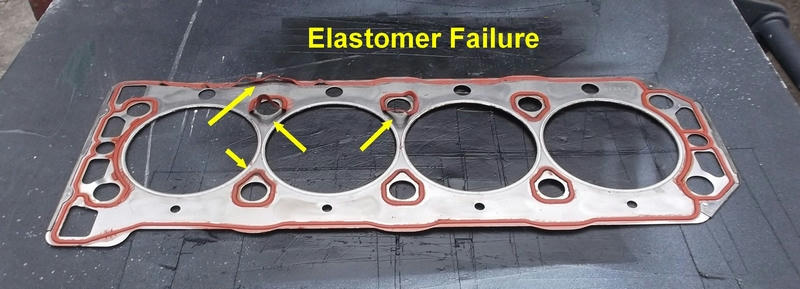

Chris, it would be interesting to see the old gasket if possible. Any chance you could ask the garage to save it for you? The typical HGF suffered by this model isn't the traditional fire ring type failure, but a simple delamination of the elastomer rings that keep the coolant and oil channels apart. Said by some to be a direct consequence of OAT plasticisation of the silcone beads. Here's what mine looked like:

I'm currently investigating the effect of 50% OAT coolant on these beads to see if the theory has merit. TC |

|

|

|

|

|

#14 | |

|

I really should get out more.......

P6B, L550, Imp, F56, Commando Join Date: Nov 2006

Location: Aberdeenshire

Posts: 2,886

Thanks: 352

Thanked 677 Times in 440 Posts

|

Quote:

Not a pretty design IMO. They should have lasered tiny slots into the metal shim to allow the elastomer to get a hold of something. I have not seen the elastomer itself actually damaged only the bond has given up. I can’t recall the elastomer type used (EPDM?) but if it is then that does not take kindly to exposure to hydrocarbon and swells up again releasing the bond over many heat and pressure cycles. |

|

|

|

|

|

|

#15 | |

|

Regular poster

MG ZT 1.8T & Lotus Elise S2 (K Series) Join Date: Aug 2012

Location: Leeds

Posts: 67

Thanks: 2

Thanked 4 Times in 3 Posts

|

Quote:

Chris |

|

|

|

|

|

|

#16 | ||

|

This is my second home

Rover75 and Mreg Corsa. Join Date: Nov 2006

Location: Sumweer onat mote o'dust (Sagin)

Posts: 21,752

Thanks: 341

Thanked 3,660 Times in 2,924 Posts

|

Quote:

Quote:

TC |

||

|

|

|

|

|

#17 |

|

This is my second home

R75 Saloon. Join Date: Feb 2009

Location: France/or Devon.

Posts: 14,003

Thanks: 3,851

Thanked 2,167 Times in 1,816 Posts

|

Having the head skimmed if it's not needed is detrimental to the job.---

|

|

|

|

|

|

#18 | ||

|

Loves to post

Rover 75 Tourer Join Date: Jul 2016

Location: Withernsea

Posts: 436

Thanks: 43

Thanked 290 Times in 167 Posts

|

Quote:

I am interested to see the results of your findings on OAT coolant as I have seen the debate countless times on here ! We have numerous K series engines running on OAT coolant What I will add is that we change the coolant within it 4 year life span and if any issues use the same Brand of coolant to replenish as a good practice ! What is the effect of aged or cross contaminated coolant when coolant is not changed as per service schedule, or if topped up with a different coolant. I have a feeling that the above issues also affects the life of the elastomer gasket Again when we have purchased a K series engined car I have changed the coolant along with the cambelt for peace of mind Head gasket problems we have had On 1.8 T Within a few months , we had problems with the fire ring indentation on a head that had been skimmed before we bought it. Elastomer on gasket fine but think it had been changed shortly before we bought it On the 1.4 Rover 45 when I bought the car it had coolant entering the sump with elastomer breakdown similar to your photo between an oil drain and the coolant Quote:

If not over heated I would just reinstate with new elastomer gasket if no damage on the head where the fire ring sits . (usually the area for concern with small pits and indentations) A Company called modus actually machines the head out and fits a new alloy rings, which if I had a head with fire ring damage , I would look into as that is a better engineering solution than skimming , after an experience's with a 1.8 T we run http://www.modusengineservices.co.uk...ep_repair.html [QUOTE=Lovel;2877095] They should have lasered tiny slots into the metal shim to allow the elastomer to get a hold of something.[/QUOTE Improved gaskets have holes through them to bond the elastomer through the gasket but original bonding of the elastomer to the gasket was designed only to hold the elastomer in place while the gasket was fitted and the tightened head compressed and held the elastomer in position . Successful to a point but will T cut experiment prove that the OAT antifreeze eventually softens the elastomer or is aged or mixing of different Antifreezes to blame causing the reaction to soften the elastomer Last edited by TourerSteve; 17th April 2021 at 18:22.. |

||

|

|

|

|

|

#19 |

|

This is my second home

Rover75 and Mreg Corsa. Join Date: Nov 2006

Location: Sumweer onat mote o'dust (Sagin)

Posts: 21,752

Thanks: 341

Thanked 3,660 Times in 2,924 Posts

|

Hello Steve. My 1.8T never had anything but 50% OAT antifreeze since new. It never overheated, yet dumped the coolant into the sump after 30K miles in thirteen years. The head gasket speaks for itself. Was it OAT or was it because the gaskets were never fit for purpose because of their poor design? We still fit elastomer gaskets without issue so where does the difference lay?

I don't believe mixing different OAT types has any greater or lesser effect than one or other alone. Mixing OAT type with a traditional no-OAT is however not good as they may very well inter-react to cause a precipitation or gelation. The service life will be reduced considerably. All this background can be found on the webpages of the antifreeze manufacturers/suppliers and on engine enthusiast sites. A simple Google for OAT antifreeze will keep you going for days. The OAT used in the early years was quite different from today's OAT, so that complicates things somewhat. The 2-EHA (2-Ethylhexanoic Acid) derivatives found in early OAT formulas is said to soften silcone rubbers and is the reason, even today. silicone hose manufacturers use a resistant inner layer to avoid the problem. Certainly, from my time in the chemical industry, I recognise 2-EHA esters as efficient plasticisers for many polymers and I've sythesised a few in my time. In the main, 2-EHA has been replaced with a non- (less?)-plasticising organic acid called sebacic. Unfortunately, no OAT manufacturer will tell Joe Public what's in their antifreeze, so Joe has to decide what to use based on the car's Handbook, the historical public record, 'expert' recommendations and hearsay. Arguably, we don't need to use a 50% antifreeze concentration to protect down to -36C. A more dilute formula like 30% is frequently recommended and will certainly protect from freezing in this part of the world. Logically, the potential for softening elastomers will be reduced as well, at least it will slow things down. However, antifreeze does a lot more than freeze prevention. What impact a significant dilution has on corrosion inhibition, water pump lubrication, foam prevention, anti-cavitation, etc. is rarely considered. Suck it and see I guess. TC |

|

|

|

|

|

#20 |

|

Regular poster

MG ZT 1.8T & Lotus Elise S2 (K Series) Join Date: Aug 2012

Location: Leeds

Posts: 67

Thanks: 2

Thanked 4 Times in 3 Posts

|

The MG is back in working order.

I have the failed gasket, pictures below, you can see where the elastomer has let go of the metal along the front edge : https://drive.google.com/file/d/1SpH...w?usp=drivesdk https://drive.google.com/file/d/1SpH...w?usp=drivesdk https://drive.google.com/file/d/1Szc...w?usp=drivesdk Thanks for everyone's input, hopefully will help others out in future! Chris |

|

|

|

|

|

|