|

||

|

|

||

|

|

||

|

|

#1 |

|

Posted a thing or two

Rover 75 Saloon Join Date: Apr 2019

Location: Under the car

Posts: 1,840

Thanks: 210

Thanked 244 Times in 221 Posts

|

Can someone tell me which fittings I need for the front pair of pipes (modulator to RH hose union & modulator to LH hose union)? I'm assuming the pipe itself is 3/16".

Also, how the hell can the RH pipe be routed past the big aircon pipes, both of which are on top of it? I can't see any way of feeding a correctly shaped brake pipe under the aircon pipes, down to the clip, up again and through the hole without mangling it completely out of shape.  This is what's left of the old RH pipe after battling to get it out!  The LH pipe.  The fitting on the modulator end.  The fitting on the hose end - the cause of all the problems. I hate these things.  This one was new a few years ago! This one was new a few years ago! |

|

|

|

|

|

#2 |

|

Posted a thing or two

Rover 75 Saloon Join Date: Apr 2019

Location: Under the car

Posts: 1,840

Thanks: 210

Thanked 244 Times in 221 Posts

|

Here's the hole with aircon pipes in front of it. Now spot the clip!

|

|

|

|

|

|

#3 |

|

Posted a thing or two

Rover 75 Saloon Join Date: Apr 2019

Location: Under the car

Posts: 1,840

Thanks: 210

Thanked 244 Times in 221 Posts

|

Ah, here it is.

Idiot designer strikes again.  Last edited by Blink; 4th September 2020 at 16:20.. |

|

|

|

|

|

#4 |

|

This is my second home

MG ZT CDTi Join Date: Jan 2014

Location: carrick

Posts: 7,859

Thanks: 3,494

Thanked 2,657 Times in 1,973 Posts

|

Rimmer's can be your friend at times like this (for guidance at least).

I havent done this myself, but the time will come soon enough I am sure, but have read of others struggles on it (hence not done it myself lol). MarinaBrian posted somewhere some pictures of his rather tasty work. In one of them, the left if I recall, he left the pipe straight for it to exit the inner arch to the flexi. Once out through the hole, he then bent it into the correct shape. I would suggest this would be a method to consider if the shapes are awkward.

__________________

It is not gloss primer .............. it is duct tape silver! |

|

|

|

|

|

#5 | ||

|

Doesn't do things by halves

Rover 75 2.5 Connoisseur Auto (1999) Dealer launch model. Join Date: Mar 2007

Location: Former Middlesex

Posts: 20,374

Thanks: 1,587

Thanked 3,749 Times in 3,181 Posts

|

Quote:

Here's my guide to brake pipe renewal which I hope you find helpful. Quote:

Simon

__________________

"Whatever is rightly done, however humble, is noble." Sir Henry Royce. |

||

|

|

|

|

|

#6 |

|

Banned

ROVER 75 Connoisseur Join Date: Jul 2020

Location: BRACKNELL

Posts: 270

Thanks: 125

Thanked 130 Times in 92 Posts

|

I have found it is only the last bend that need to formed on the car, the one after it passes through the grommet in the suspension turret.

Looking at the pipes you removed.........they appear to have been replaced as they are cupro-nickel, I have to ask why you were changing them?? By the way the fittings are not UNF, but 10mm metric on both ends, with a single flare on each end. |

|

|

|

|

|

#7 |

|

This is my second home

Rover75 and Mreg Corsa. Join Date: Nov 2006

Location: Sumweer onat mote o'dust (Sagin)

Posts: 21,753

Thanks: 341

Thanked 3,660 Times in 2,924 Posts

|

I've provided my pipe ftting experiences in your other thread here: https://www.the75andztclub.co.uk/for...d.php?t=307648

TC |

|

|

|

|

|

#8 | ||||

|

Posted a thing or two

Rover 75 Saloon Join Date: Apr 2019

Location: Under the car

Posts: 1,840

Thanks: 210

Thanked 244 Times in 221 Posts

|

Quote:

I did see Brian's post some time ago but the pics have gone from it now so I can't see what he's describing - should have made a pdf copy! I do remember him saying he'd left the wheel arch side straight to get through the hole. The LH is probably easy-ish but the RH is obviously much harder due to the aircon pipes and the clip being all in one spot. I might try making a template out of some 2.5mm electrical cable (one wire thereof). Quote:

The brake pipes were obviously pre-shaped before the factory fitted them. I'll bet the front ones went in before the aircon and engine did. Quote:

So I need 3/16" pipe - I'd prefer cupro-nickel but copper would be easier for a novice piper bender like me to shape. Then I need four 10mm x 1 fittings - I think I'll go for the stainless ones in your link on the other thread (post 4). What's a single flare mean? Told you I was a novice pipe bender.  Quote:

Anyway, I'll read and digest your post 5 - thanks for taking the time to go into such detail. Pics too! We likes pics.  |

||||

|

|

|

|

|

#9 |

|

This is my second home

Rover75 and Mreg Corsa. Join Date: Nov 2006

Location: Sumweer onat mote o'dust (Sagin)

Posts: 21,753

Thanks: 341

Thanked 3,660 Times in 2,924 Posts

|

A single flare is one swaging operation using the flaring die. Depending on the die type, it results in either a funnel shaped end or a 'bubble' shaped end. Another different die is applied as a second step to to convert a balloon shape into a double walled funnel shape.

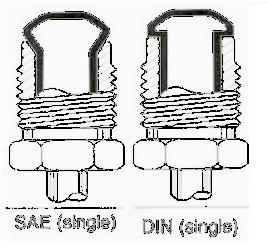

The single funnel flare is not used for hydraulic brake applications because the thin wall does not produce an adequate compession seal. The double flare is an old brakes standard largely superceded by the bubble styles. The bubble flare is widely used around the world and comes in two flavours.  The different shapes are created by the using different dies (SAE or DIN). You need the DIN style. Note that each bubble flare type needs a specific type of compression nut. Note the different compression surfaces on the nuts. So, there are SAE nuts and DIN nuts. These male nuts also come in two lengths. You need two of the DIN Short type for each front brake. If questions arise about installing your front pipes, my experience is still fresh in mind, so I'll try to help. TC Last edited by T-Cut; 6th September 2020 at 17:17.. |

|

|

|

|

|

#10 |

|

Banned

ROVER 75 Connoisseur Join Date: Jul 2020

Location: BRACKNELL

Posts: 270

Thanks: 125

Thanked 130 Times in 92 Posts

|

SAE (Society of Automotive Engineering) fittings tend to be UNF threadform, and DIN (Deutsches Institut fur Nomung) fitting metric.

A "bubble" flare is what I understood to be a single flare, and the double flare is a "bubble" flare which has had a second application with another die to form a cone. The double flare is used where there is a convex cone on the mating fitting. So the advice is to form a single flare of DIN type on each end of the pipe from the modulator to the front flexi pipes. Last edited by ADO282; 6th September 2020 at 20:06.. |

|

|

|

|

|

|